When I first stepped into the world of power transmission, the term “high voltage cable” sounded intimidating—charged with both mystery and, well, high voltage. But as I came to understand, these cables are the essential arteries of our electrical systems, quietly powering homes, industries, and cities. Whether you’re a project manager, engineer, or simply new to electrical infrastructure, this guide is written for you. Let’s demystify high voltage cables together, walk through their role, structure, and practical installation tips, and help you make informed choices for your next project.

What is a High Voltage Cable?

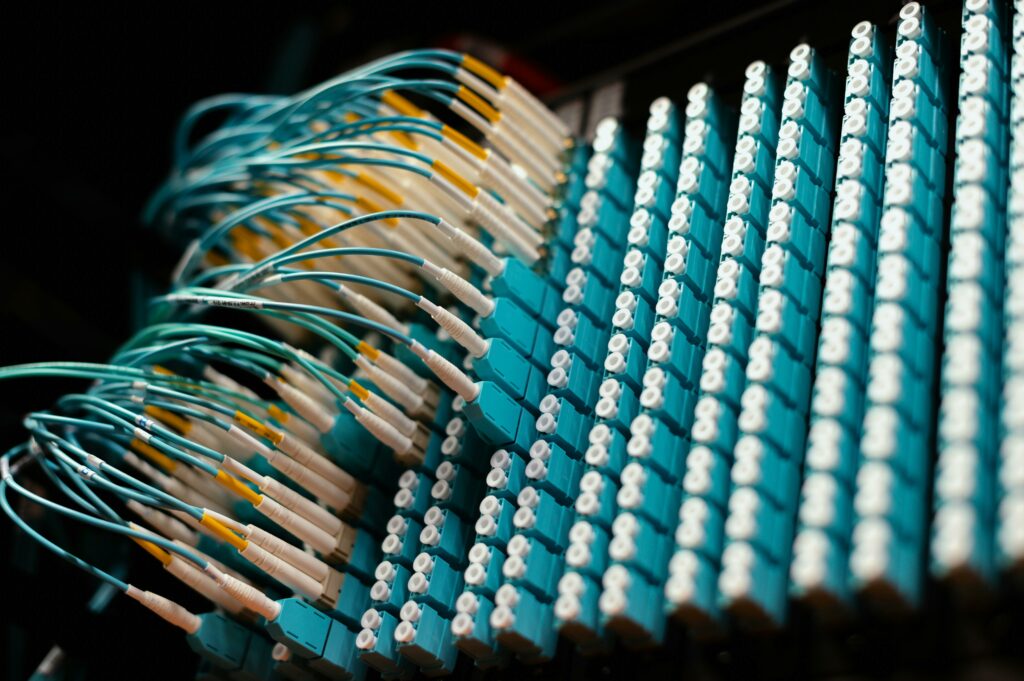

High voltage (HV) cables are designed to transmit electrical energy at voltages from 1kV up to 1000kV. You’ll find them carrying power over long distances from generating stations to substations, and sometimes distributing electricity within urban grids. If you think of the human body, high voltage cables act much like major arteries—efficiently moving energy where it’s needed most with minimal loss.

Unlike traditional wiring, these cables are engineered to handle high electrical stress, provide mechanical protection, and offer robust insulation. They are commonly used both for overhead and underground power transmission in city centers and industrial environments, where reliability and safety are non-negotiable.

Where Are High Voltage Cables Used?

One of the remarkable things about HV cables is their versatility:

- Urban Power Grids: Buried underground to save space and enhance city aesthetics, as well as reduce exposure to accidents or severe weather.

- Industrial Facilities: Connecting substations and heavy machinery, ensuring stable power for production activities.

- Renewable Energy: Transmitting solar or wind-generated electricity to the grid.

- Transportation: Providing power for metro lines, high-speed railways, and traffic management systems.

In fact, nearly every major modern infrastructure project relies on high voltage cables at some stage.

How Does a High Voltage Cable Work?

I like to imagine a high voltage cable as a well-armored train carrying valuable cargo (electricity) through a tunnel. It has several protective layers, each with a specific job:

| Component | Description |

|---|---|

| Conductor | The track, usually made of copper or aluminum, efficiently carries the electric current. |

| Insulation | Surrounds the conductor, preventing electricity from escaping—often cross-linked polyethylene (XLPE) or polyvinyl chloride (PVC). |

| Shield/Bedding | A metallic layer (like aluminum or copper tape) provides electromagnetic shielding and blocks interference. |

| Armor (Optional) | Like chainmail for the cable—steel wire or tape armor guards against mechanical stresses, especially when cables are buried or exposed to harsher environments. |

| Sheath | The outer skin, typically PVC or polyethylene, protects the whole assembly from moisture, chemicals, or abrasion. |

This multi-layer structure is integral to durability and safety. For buried HV cables, armoring is especially important, much like a subway system needs sturdy tunnel linings for protection.

Types of High Voltage Cables

The choice of HV cable depends not only on voltage, but also on the environment and application. Here are some of the most common types I’ve worked with or recommended to clients:

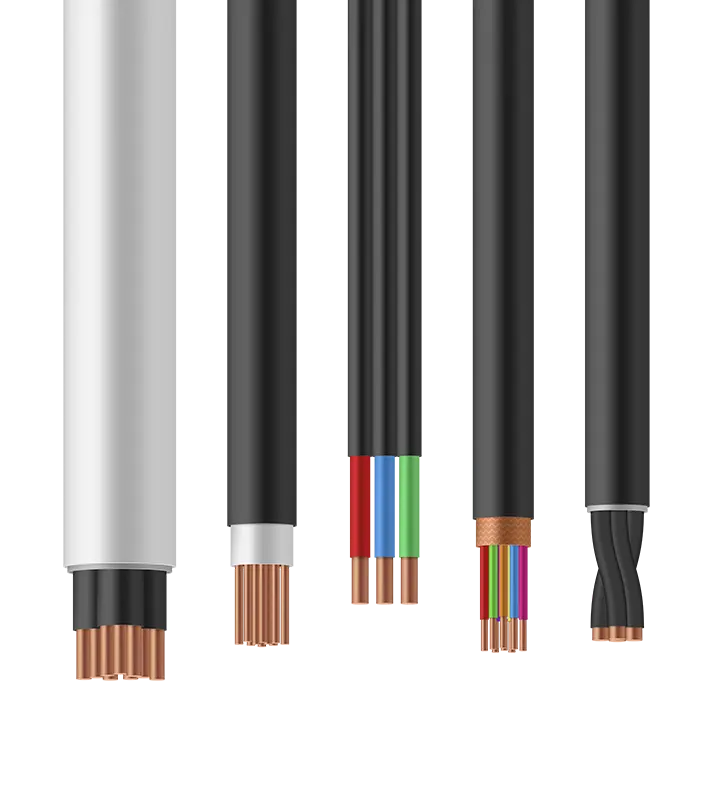

By Conductor Material

Copper Core: Offers outstanding conductivity and mechanical strength—preferred for high and extra-high voltage applications.

Aluminum Core: Lighter and more economical, though usually reserved for medium and lower voltage applications.

By Structure

Single Core or Multi-Core: Depending on power requirements and installation needs (single for transmission, multi-core for distribution).

Armored vs Non-Armored: Armoring is crucial for underground or exposed environments.

By Insulation and Sheathing

XLPE-Insulated Cables (e.g., YJV): Known for high mechanical strength and thermal endurance.

PVC-Insulated Cables (e.g., VV): Widely used, cost-effective, and easy to install.

If you want to explore a full range of high voltage power cables—including XLPE and armored options—LX CABLE offers a dedicated category for Power Cables tailored for demanding environments.

Typical Applications and Installation Scenarios

Depending on the scenario, the cable you select can have a big impact on system resilience and cost-effectiveness:

- Indoor and Tunnel Installations: Fire-retardant or low-smoke, halogen-free cables are often recommended.

- Direct Burial: Steel-tape armored or double-sheathed cables help resist external mechanical forces and moisture.

- Cable Trays or Racks: Unarmored cables with suitable sheathing may suffice, especially in protected environments.

For instance, industrial zones will often use armored, copper-core HV cables, while utility companies may opt for cost-effective aluminum-core cables for overhead transmission lines. We’ve even supplied solution packages for renewable power plants, where long-lasting and weather-resistant cables are a must.

How to Choose the Right High Voltage Cable for Your Project

This isn’t just about picking a cable and calling it a day. You’ll need to factor in:

| Factor | Consideration |

|---|---|

| Voltage and Load Requirements | Always select a cable rated for the maximum voltage and current expected in your application. |

| Installation Environment | Underground? Overhead? Indoors? Each scenario affects the necessary protective measures. |

| Cable Length and Routing | Longer runs might require extra insulation or larger conductor sizes to minimize power loss. |

| Regulatory Compliance | Be sure your choice meets national and international standards for safety and quality. |

With over 25 years of experience, our team at LX Cable has guided hundreds of customers through this decision process. Whether you’re designing a new substation or upgrading a city grid, reaching out for technical support can make all the difference.

Best Practices for High Voltage Cable Installation

Proper installation is as important as cable selection. Here’s what I’ve learned over years of hands-on projects:

Use Proper Tools and Accessories

Ensure that connectors, clamps, and support brackets match your cable’s specifications. You may want to explore our range of power line hardware for compatible installation products.

Control Bending Radius

Never bend cables below their specified minimum radius, as this can damage internal insulation and lead to failure.

Maintain Cleanliness

Always keep cable ends clean during splicing or connection, and avoid contaminants entering insulation layers.

Test After Installation

Routinely perform voltage and insulation resistance tests before energizing cables—safety should always come first.

If you’re new to installation, consider working with a certified installer or reaching out for technical training.

Safety Advice for High Voltage Cables

It goes without saying, but I’ll say it anyway: high voltage is dangerous. Even if you’re just handling cables, never neglect personal protective equipment (PPE), adhere to lockout/tagout standards, and consult with an experienced professional if you have any doubts.

I often compare high voltage systems to busy highways: proper barriers, rules, and signage keep things running safely. In the world of HV cables, robust insulation, protective armor, and rigorous testing play the same role.

Why Choose LX Cable for High Voltage Projects?

Our expertise isn’t limited to manufacturing top-tier cables—we also provide one-stop solutions and after-sales support to guide you from specification to final installation. All of our products undergo strict quality checks, as detailed on our Quality Assurance page. Sustainability, cost-efficiency, and fast delivery are promises we keep for every order.

Ready to learn more? Explore all our high voltage power cables or see our power line hardware solutions for end-to-end project support.

Conclusion: Start Your High Voltage Cable Project with Confidence

While high voltage cable systems are complex, the principles are straightforward: choose the right type, ensure quality installation, and rely on expert guidance when needed. At LX Cable, we’re passionate about making high voltage solutions accessible and reliable for everyone—whether it’s your first project or your hundredth.

If you have specific requirements or installation challenges, our engineering team is just a click away. Contact us today to get custom advice, technical support, or a detailed quotation for your next power transmission project.

High voltage isn’t just about potential—it’s about powering possibilities. Let’s move forward together.