As we delve into the fascinating world of electrical systems, one component often goes unnoticed yet plays a crucial role in ensuring safety and efficient power transmission: the electrical insulator. These seemingly simple devices are essential for maintaining the integrity of electrical circuits by preventing unwanted current leakage. In this guide, we’ll explore the fundamental aspects of insulators and the various types you might encounter.

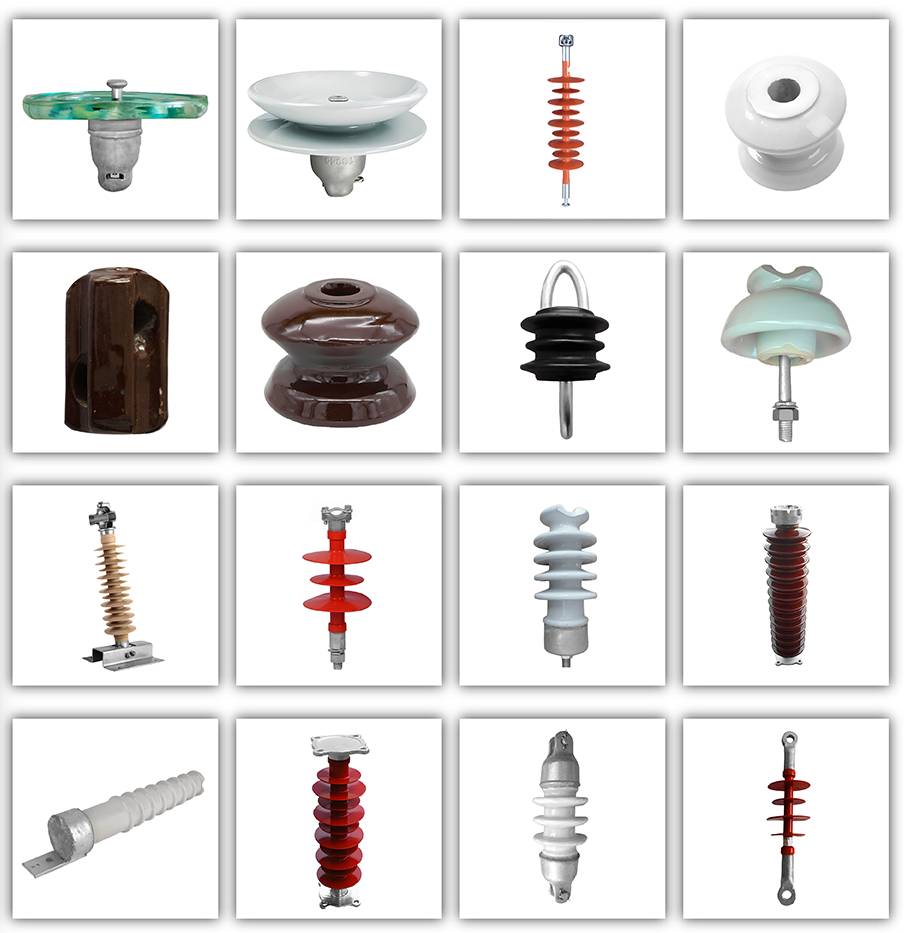

At its core, an insulator is a device designed to withstand both electrical voltage and mechanical stress, positioned between conductors at different electrical potentials or between a conductor and a grounded component. You’ll find a wide array of insulator types, each with its unique shape and structure. While their designs may vary significantly, all insulators fundamentally consist of two main parts: the insulating body and the connecting hardware.

Think back to the early days of power lines, where insulators were primarily used on wooden poles. Over time, as voltage levels increased, so did the sophistication of insulators. Today, you often see strings of disc-shaped insulators hanging from high-voltage transmission towers. These multiple discs increase the creepage distance – the path along the surface of the insulator – which enhances insulation performance, especially in wet or contaminated conditions. Traditionally, these discs are made from materials like glass or ceramic.

It’s crucial to understand that insulators must maintain their integrity despite changing environmental conditions and electrical loads. Failure due to mechanical or electrical stresses can compromise the entire power line, significantly impacting its lifespan and operational efficiency.

Classifying Electrical Insulators

To better understand the diverse world of insulators, we can categorize them based on several key characteristics:

1. By Installation Method

Suspension Insulators: These are widely used in high-voltage overhead transmission lines and for insulating and mechanically securing flexible busbars in power plants and substations. Within this category, you’ll find disc-type suspension insulators, the most common type in transmission lines, and rod-type suspension insulators, which are gaining popularity in some regions.

Pin-Type Insulators: Primarily used for insulating and mechanically fixing busbars and electrical equipment in power plants and substations. They also often form part of other electrical apparatus like disconnect switches and circuit breakers. Pin-type insulators can be further divided into pin-type post insulators, commonly seen in low-voltage distribution and communication lines, and rod-type post insulators, frequently used in high-voltage substations.

2. By Insulation Material

Porcelain Insulators: The insulating part of these insulators is made from electrical porcelain, a ceramic material produced by firing a mixture of quartz, feldspar, and clay. The porcelain surface is typically glazed to enhance mechanical strength, prevent water absorption, and create a smoother surface. Porcelain insulators are among the most widely used due to their reliability and cost-effectiveness.

Glass Insulators: These insulators utilize toughened glass for their insulating component. A unique characteristic of glass insulators is their behavior under failure. If a crack or electrical breakdown occurs, the glass insulator shatters into small fragments, a phenomenon known as “self-shattering.” This self-diagnostic feature eliminates the need for “zero-value” detection during operation.

Composite Insulators: Also known as synthetic insulators, these consist of a fiberglass resin core rod (or tube) and an organic material housing with sheds and skirts. They are characterized by their small size, light weight, high tensile strength, and excellent resistance to flashover in polluted environments. However, their resistance to aging may not be as high as that of porcelain and glass insulators. Composite insulators encompass various types, including rod-type suspension insulators, insulating cross-arms, post insulators, and hollow insulators (composite bushings). Composite bushings can replace porcelain bushings in various power equipment like transformers, surge arresters, circuit breakers, capacitor bushings, and cable terminations, offering advantages such as high mechanical strength, light weight, and tight dimensional tolerances, while also preventing damage from shattering.

3. By Voltage Level

Low-Voltage Insulators: Designed for use in low-voltage distribution and communication lines.

High-Voltage Insulators: Intended for high and extra-high voltage overhead transmission lines and substations. To accommodate different voltage levels, multiple single insulator units of the same type are often connected in series to form insulator strings or multi-section insulator posts.

4. By Environmental Conditions

Anti-Pollution Insulators (Contamination-Resistant Insulators): These are specifically designed for use in areas with high levels of pollution. They typically feature increased creepage distance achieved by larger or a greater number of sheds and skirts. The shape of the sheds and skirts is also optimized to minimize natural pollution accumulation, thereby improving their resistance to flashover caused by contamination. The specific creepage distance of anti-pollution insulators is generally 20% to 30% or even more than that of ordinary insulators. In regions prone to pollution flashovers, double-shed insulators are commonly used due to their strong self-cleaning ability and ease of manual cleaning.

5. By Voltage Type

DC Insulators: Primarily used in direct current (DC) transmission systems. DC insulators generally have longer creepage distances than AC anti-pollution insulators. Their insulating components exhibit higher volume resistivity (not less than 10 Ω⋅m at 50°C), and their connecting hardware is often equipped with sacrificial electrodes (like zinc sleeves or rings) to prevent electrolytic corrosion.

6. By Breakdown Characteristics

Type A (Non-Puncture Type) Insulators: These are designed such that their dry flashover distance is no more than three times (for cast resin types) or two times (for other materials) their dry puncture distance.

Type B (Puncture Type) Insulators: In these insulators, the puncture distance is less than one-third (for cast resin types) or one-half (for other materials) of their dry flashover distance. The dry flashover distance refers to the shortest path through the air along the outer surface of the insulating part, while the puncture distance is the shortest path through the insulating material itself.

Key Functions and Requirements

The primary functions of an insulator are to provide electrical insulation and mechanical support. To achieve this, various electrical and mechanical performance requirements are specified. For instance, under specified operating voltage, lightning overvoltages, and internal overvoltages, the insulator must not experience breakdown or flashover along its surface. Similarly, it must withstand specified long-term and short-term mechanical loads without failure or damage. Furthermore, it should not exhibit significant degradation after prolonged operation under specified mechanical, electrical, and environmental conditions. The insulator’s hardware should also be designed to prevent noticeable corona discharge under operating voltage to avoid radio or television interference. Given the large quantities in which insulators are used, interchangeability of their connecting hardware is also a crucial requirement.

Additionally, technical standards for insulators dictate various electrical, mechanical, physical, and environmental tests based on their type and application conditions. These tests are essential to verify their performance and quality.

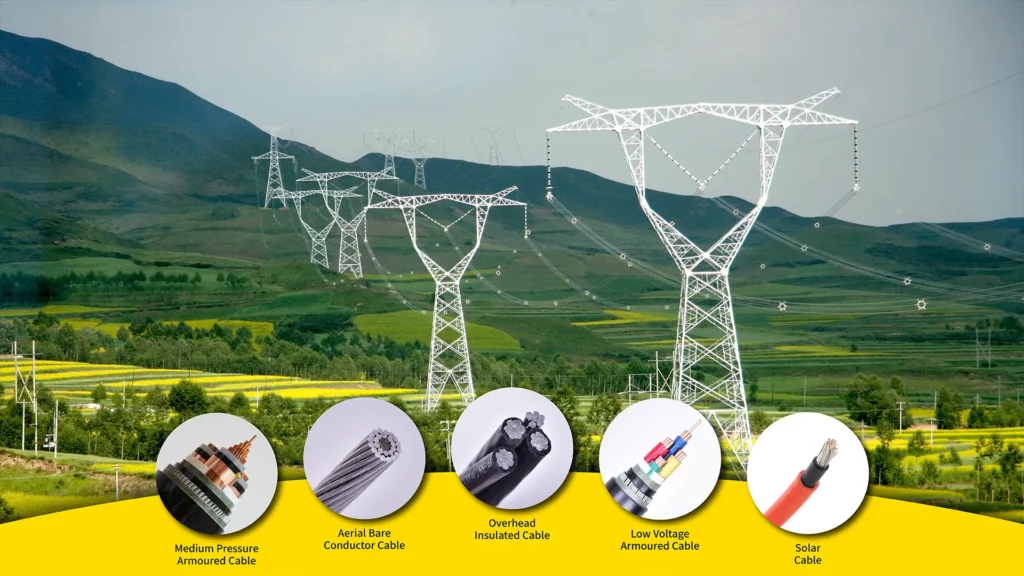

From Power Cables to Fiber Optics: LX Cable Connecting the World

As LX Cable, we are a leading cable manufacturer and solutions provider with over two decades of experience, originating in China in the 1990s. We specialize in a comprehensive range of power transmission solutions, including the production and sales of power cables, overhead cables, electrical wires, photovoltaic cables, and optical fiber cables. We are proud to offer OEM services and have expanded our reach from the domestic market to over 150 countries and regions worldwide. Our commitment is to provide reliable and efficient turnkey solutions for electrical products, ensuring every product meets high standards for our clients across various industries.

Conclusion

Electrical insulators are indispensable components in power systems, ensuring the reliable and safe transmission and distribution of electricity. Understanding the different types of insulators and their specific applications is crucial for anyone involved in electrical engineering or maintenance. From the robust porcelain and glass insulators to the lightweight and high-performance composite options, each type plays a vital role in keeping our modern world powered.

If you have further questions about electrical insulators or require assistance with your specific needs, please don’t hesitate to contact us. We’re here to help!