A fundamental question in the electrical world is both simple and critical: how many parts make up an electric cable? For engineers, contractors, and industry experts, mastering this knowledge is essential. Each component contributes to performance, safety, and durability.

By understanding the structure of a cable from low voltage lines to complex medium voltage systems, you gain the insight needed to design, install, and maintain electrical networks with confidence. In the following sections, we will break down the key parts of an electrical cable and explain their roles in detail.

Main Parts of an Electrical Cable

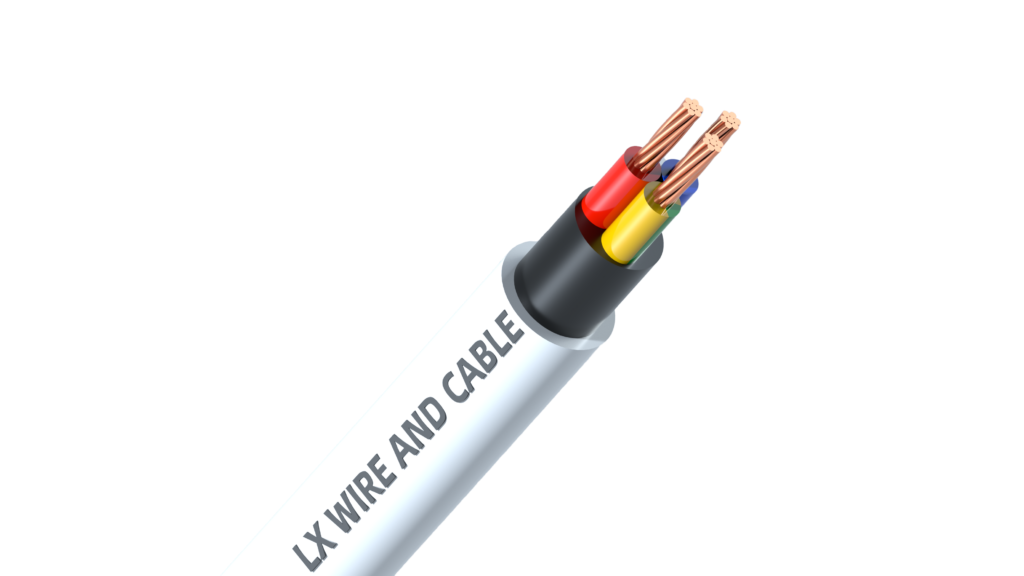

А standard electrical cable normally consists of three basic parts: the conductor, the insulation, and the outer sheath (sometimes called the jacket). These three layers form the foundation of almost every power cable design under international standards such as IEC and TCVN. Depending on the application, additional layers may be added, but these three are always present.

Conductor – The Core That Carries Current

The conductor is the heart of any cable. Its purpose is to carry current safely and efficiently. Both the choice of material and the structure of the conductor have a direct impact on resistance, current-carrying capacity, and overall performance.

Resistivity values at 20 °C:

- Copper (Cu): about 0.017241 Ω·mm²/m.

- Aluminum (Al): about 0.0283 Ω·mm²/m.

This means aluminum has roughly 1.6 times higher resistivity than copper. In practice, to carry the same current, an aluminum conductor needs a larger cross-sectional area.

Density comparison:

- Copper: 8.96 g/cm³

- Aluminum: 2.70 g/cm³

Aluminum is lighter and cheaper, which makes it popular in overhead power lines and large installations. Copper, however, provides higher conductivity, better flexibility, and stronger mechanical durability.

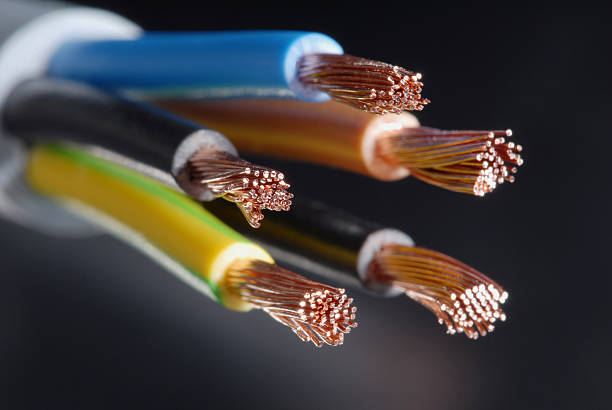

Types of conductor construction:

- Solid conductor: One single wire, cost-effective, often used in fixed domestic wiring.

- Stranded conductor: Multiple small wires twisted together, providing flexibility and easier installation in machinery or movable systems.

- Compacted stranded conductor: Stranded wires are compressed to reduce gaps, producing a smoother, denser conductor that improves performance and reduces corrosion risk.

The correct conductor design depends on load requirements, installation method, and environmental conditions. Choosing a conductor that is too small can cause overheating, energy loss, or even safety hazards.

Insulation – The Electrical Barrier

The insulation layer surrounds the conductor and keeps the current inside. It prevents short circuits, electric shocks, and leakage currents. High-quality insulation is one of the most important factors in extending a cable’s service life.

Common insulation materials and performance:

| Материал | Rated Temperature | Преимущества | Limitations |

| PVC (Polyvinyl Chloride) | Up to 70 °C | Low cost, easy to process, fair chemical resistance | Ages faster in high heat or harsh environments |

| XLPE (Cross-Linked Polyethylene) | Up to 90 °C continuous, 250 °C short-circuit | Excellent thermal stability, high dielectric strength | Higher cost, more complex manufacturing |

| Rubber compounds | Varies | Flexible, impact resistant, ideal for portable and industrial cables | Limited voltage range, less suitable for extreme heat |

| Special polymers (Silicone, Fluoroplastics) | Up to 200–250 °C | Extreme temperature and chemical resistance | High cost, specialized applications |

Outer Sheath (Jacket) – The Protective Skin

The outer sheath is the cable’s first defense against the outside world. It protects the inner components from physical damage, moisture, chemical attack, UV radiation, and even rodents.

Typical sheath materials:

- PVC sheath: Standard choice for general indoor and light-duty outdoor use.

- PE (Polyethylene): Strong resistance to water and chemicals, widely used in buried or outdoor applications.

- LSZH (Low Smoke Zero Halogen): Essential in tunnels, metro systems, and public buildings; releases minimal smoke and no toxic halogen gases during fire.

- FR-PVC or flame-retardant compounds: Designed to maintain performance in fire conditions.

The outer sheath works differently from the insulation. While insulation focuses on electrical safety, the sheath ensures mechanical strength and environmental resistance. The thickness, additives (such as UV stabilizers and anti-aging agents), and formulation of the sheath directly influence how long the cable can survive in harsh conditions.

Additional Components in Electrical Cables

The three main parts, including conductor, insulation, and outer sheath, form the essential structure of every electrical cable. However, many cables include additional layers to meet higher demands for safety, durability, and performance in specific environments. These components are not secondary details; they play a central role in reliability, installation quality, and long-term service life.

Bedding (Inner Sheath) – Mechanical Cushion

The bedding, also called the inner sheath, sits between insulation and armor. Its primary role is to act as a buffer. Without bedding, the sharp edges of armor wires could press against the insulation and cause premature breakdown. Bedding is usually made from PVC or thermoplastic materials.

Key Functions:

• Maintains the round shape of the cable for uniform stress distribution

• Protects insulation from mechanical damage caused by armor

• Improves installation quality by keeping layers smooth and stable

Shielding – Defense Against Interference

When cables carry control signals or data, electromagnetic interference (EMI) can be a serious issue. Shielding prevents external noise from disturbing signals and also reduces electromagnetic emissions from the cable itself.

Common Shield Types and Effectiveness

| Shield Type | Typical Material | Application Example | Shielding Efficiency* |

| Foil Shield | Aluminum + polyester tape | Data and instrumentation | ~100% coverage, strong at high frequencies |

| Braided Shield | Copper wires woven | Industrial control systems | 70–95% coverage, effective at low frequencies |

| Combination (Foil + Braid) | Foil with copper braid | High-performance cables | High efficiency across broad frequency range |

*Efficiency values are indicative and vary with design.

Armoring – Protection Against Impact

Armoring is essential where cables face mechanical stress. Steel wire armor, or SWA, is commonly used in power distribution. It can resist crushing forces that exceed 2,000 N in certain designs. Aluminum wire armor, or AWA, is much lighter, sometimes nearly 50 percent less weight than SWA, which makes it suitable for vertical installations or applications where weight must be reduced.

Fillers – Structural Stability

Fillers are placed in the empty spaces between conductors in multicore cables. Although simple in appearance, they help the cable remain round and compact, preventing distortion during bending.

Materials Commonly Used:

• Polypropylene (PP), which is lightweight, moisture resistant, and widely used in modern designs

• Natural fibers such as jute, which are traditional options still found in certain cable types

Cables without proper fillers may deform under stress. This can complicate termination and reduce long-term reliability.

Special Layers – Advanced Protection

Some environments require more than standard protection. Fire-resistant layers, such as mica tape, allow cables to maintain circuit integrity for 90 to 120 minutes under fire conditions, meeting IEC 60331 standards. High-temperature barriers made of silicone rubber or glass fiber can withstand continuous operation at up to 250 °C. In fiber optic cables, aramid yarns are included as strength members, capable of handling tensile loads above 1,500 N during installation.

These specialized layers are selected according to the operational environment. They are essential in demanding applications such as power plants, tunnels, offshore platforms, and data centers where both safety and uninterrupted service are critical.

Final Thoughts

Understanding the parts of electrical cables is essential for anyone involved in power systems, installation, or procurement. At Провода и кабели LX, we provide high-quality power cables designed to meet a wide range of applications. Our team can help you select the right conductor, insulation, and protective layers to ensure safety, efficiency, and long-term performance.

Contact us today to discuss your project requirements, request samples, or explore our full range of industrial and specialty cables. With decades of global experience, we help you make informed decisions that deliver reliable results.

FAQs

1. What are the main parts of an electrical cable?

A standard electrical cable has three main parts: conductor, insulation, and outer sheath. Some cables include additional layers like shielding, bedding, or armoring for specific applications.

2. What materials are used for cable conductors, and how do I choose?

Copper and aluminum are the most common. Copper has higher conductivity and durability, while aluminum is lighter and more cost-effective. Choice depends on current, installation, and budget.

3. What are common insulation materials in cables?

PVC, XLPE, and rubber are widely used. PVC is affordable for general use, XLPE handles high temperatures and voltages, and rubber offers flexibility for industrial or portable cables.

4. What is the role of the outer sheath?

The outer sheath protects the cable from mechanical damage, moisture, chemicals, and UV exposure. It also improves durability and safety.

5. What is cable shielding and why is it important?

Shielding, made from metal tape or braid, prevents electromagnetic interference and ensures signal integrity in control, data, or instrumentation cables.