You might not notice them, but industrial cables are the lifelines of modern factories and production systems. They carry power, transmit control signals, and support high-speed data, keeping machinery and networks running safely and efficiently. In this guide, you will discover the most common industrial cable types and their functions. This knowledge can help you make smarter decisions and ensure your systems stay reliable every day.

What Are Industrial Cables?

Industrial cables are specialized electrical cables designed to power, control, and connect industrial equipment. They’re built to handle heavy loads, transmit precise signals, and operate reliably in demanding environments. In factories, plants, and construction sites, these cables ensure that power and data flow smoothly across machines, control panels, and automation systems.

Unlike regular household wires, industrial cables are made for endurance. They often work under high voltage, high temperature, or continuous mechanical stress. To withstand these conditions, they’re constructed with durable insulation materials such as XLPE, EPR, or PVC, and sometimes include protective layers like metal armor or braided shields. These features prevent electrical faults, signal interference, and physical damage.

Industrial cables are generally divided into two main categories. Functional cables are selected based on their transmission purpose, such as power, control, or communication. Specialty cables, on the other hand, are engineered for challenging or extreme environments—like high temperatures, chemical exposure, or continuous motion. Together, these two groups cover nearly every industrial need, from factory automation to heavy-duty power distribution.

Functional Industrial Cables

These are the core of industrial systems, which are the types you’ll find in nearly every facility. They handle the main flow of power, data, and control signals that keep equipment synchronized and productive.

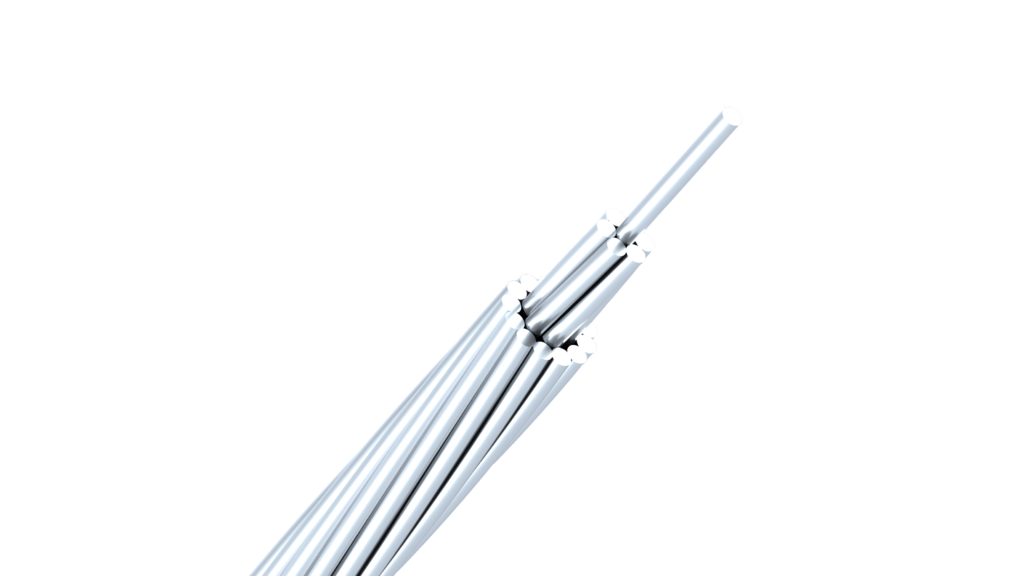

Power Cables

Power cables are designed to transmit electrical energy from generation to end-use equipment. You’ll find them in substations, industrial plants, and building infrastructure. Most use copper or aluminum conductors with PVC or XLPE insulation, ensuring durability and safety under various load conditions. They come in multiple voltage levels, such as 0.6/1 kV, 6 kV, and 10 kV, suitable for both indoor and outdoor installations.

Quality certifications: IEC 60502, VDE 0276, GB/T 12706, CE, CCC

Pros and Cons: Excellent electrical performance and long service life, but less flexible and heavier for dynamic use.

Control Cables

Control cables carry signals that operate and monitor equipment. They’re vital in automation systems, conveyor lines, and control panels. These cables often feature multi-conductor copper cores with optional shielding to prevent interference. The insulation is typically PVC or XLPE, offering good flexibility and flame resistance. Some models comply with FT-4 or LSZH safety grades for low-smoke and halogen-free performance.

Quality certifications: IEC 60227/60245, UL 2464, CSA, RoHS

Pros and Cons: Stable signal control and easy installation, though not ideal for applications requiring high mechanical strength.

Instrumentation Cables

Instrumentation cables transmit low-level analog or digital signals in sensitive systems like oil refineries, power plants, and process automation. They use twisted pairs or triads with aluminum foil and braid shielding to block electromagnetic interference. This ensures precision and stability in long-distance measurement and control.

Quality certifications: IEC 60584, BS 5308, UL 13, CE, TÜV

Pros and Cons: High accuracy and noise resistance, but unsuitable for high-voltage or power transmission.

Data & Communication Cables

These cables form the nervous system of industrial networks. Common types include Ethernet (Cat5e/Cat6), Profibus, and Profinet cables. Designed for high-speed data transfer, they feature twisted pairs with foil or braid shielding, and durable outer jackets made from PVC, PUR, or TPE. They’re built to resist oil, abrasion, and electromagnetic interference, ensuring stable communication even in harsh environments.

Quality certifications: ISO/IEC 11801, TIA/EIA 568, UL 444, CE, RoHS

Pros and Cons: Fast and reliable data transmission; however, sensitive to excessive bending or pulling.

Flexible & Robotic Cables

Used in robotics, cable chains, and moving machinery, these cables are designed for motion. They use extra-fine copper strands (Class 6) and PUR or TPE sheaths, allowing high flexibility and durability during repetitive bending. Some can endure over 10 million flex cycles, making them ideal for automation lines and robotic arms.

Quality certifications: IEC 60228, UL 758, EN 50525, CE, RoHS

Pros and Cons: Exceptional flexibility and mechanical endurance, though costlier and not suited for fixed installations.

Fiber Optic Cables

Fiber optic cables transmit data through light signals, providing high bandwidth and immunity to electromagnetic interference. They’re used in industrial IoT systems, smart factories, and communication networks. Two main types exist: single-mode (SM) for long-distance communication and multi-mode (MM) for shorter, high-capacity links.

Quality certifications: ISO 11801, IEC 60794, TIA/EIA 568, UL 1651

Pros and Cons: Offer lightning-fast, interference-free transmission; require careful handling due to fragile fibers.

Key Information of Functional Industrial Cables

| Cable Type | Applications | Key Features | Technical Specs |

| Power Cable | Power transmission in plants, substations, and machinery. | Copper or aluminum conductor, PVC/XLPE insulation. | Voltage: 0.6/1 kV – 10 kV; Temp: –15°C ~ +90°C; Flame-retardant per IEC 60332. |

| Control Cable | Control panels, automation systems, machinery wiring. | Multi-core, optional shielding, LSZH or PVC sheath. | Voltage: 300/500 V; Temp: –30°C ~ +80°C; Flame rating: FT-4 or LSZH. |

| Instrumentation Cable | Measurement and control in process industries. | Twisted pairs/triads, foil or braid shield. | Voltage: 300/500 V; Temp: –40°C ~ +85°C; EMI protection per IEC 60092-376. |

| Data & Communication Cable | Industrial Ethernet, fieldbus, sensor networks. | Cat5e/Cat6, shielded pairs, oil & abrasion resistant. | Bandwidth: up to 1 Gbps; Temp: –40°C ~ +90°C; Oil & abrasion resistant. |

| Flexible & Robotic Cable | Moving machinery, robotics, cable chains. | Fine-stranded copper, PUR/TPE sheath, high flexibility. | Voltage: 300/500 V; Flex life: >10 million cycles; Temp: –40°C ~ +105°C. |

| Fiber Optic Cable | High-speed data links, smart factories, IoT networks. | Glass fiber core, armored or non-armored, EMI immune. | Types: SM/MM; Temp: –20°C ~ +80°C; High bandwidth > 10 Gbps. |

Specialized Industrial Cables

Some environments demand more than standard performance. In such cases, specialty cables come into play—each designed to withstand extreme temperature, pressure, or chemical exposure while maintaining safety and performance.

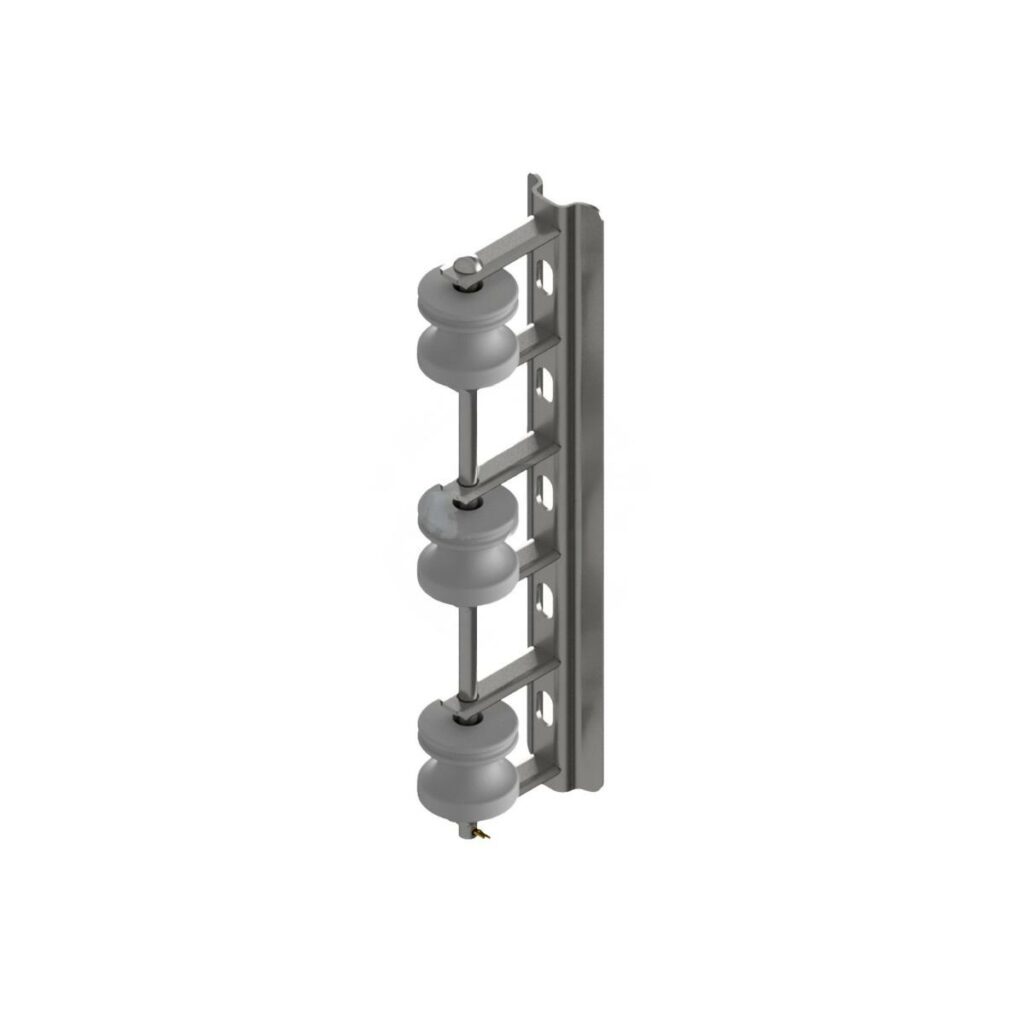

Armored Cables

Armored cables feature a steel wire (SWA) or steel tape (STA) layer that shields the cable from crushing, cutting, or impact. They’re widely used in underground installations, outdoor wiring, and mechanical workshops where durability and safety are crucial. The metal armor provides mechanical protection while maintaining good flexibility.

Quality certifications: IEC 60502-1, BS 5467, UL 1569, CE, CCC

Pros and Cons: Outstanding mechanical strength and protection against physical damage, but heavier and less flexible than standard cables.

Fire-Resistant & Flame-Retardant Cables

These cables ensure circuit integrity during a fire. Fire-resistant types can keep systems running for up to 3 hours at 750–950°C, while flame-retardant ones prevent the fire from spreading along the cable. They’re essential for emergency systems, tunnels, and high-rise buildings. Typical insulation materials include mica tape, LSZH compounds, and XLPE.

Quality certifications: IEC 60331, IEC 60332, BS 6387, CSA FT-4, RoHS

Pros and Cons: High fire endurance and safety compliance; however, higher cost and stiffness make them harder to install.

High-Temperature Cables

In industries like steelmaking, glass production, and chemical processing, cables often face extreme heat. High-temperature cables use silicone rubber, PTFE, or fiberglass insulation, operating reliably from 150°C up to 300°C. They prevent signal loss and insulation breakdown, even in continuous high-heat zones.

Quality certifications: IEC 60245-3, UL 5128, EN 50525, CE

Pros and Cons: Excellent thermal resistance and stable performance; not suitable for areas exposed to mechanical abrasion or oil.

Low-Temperature Cables

When temperatures drop below freezing, ordinary PVC cables stiffen and crack. Low-temperature cables remain flexible and functional even at –60°C. They are ideal for cold storage facilities, Arctic operations, and aviation systems. The outer sheath is usually made from TPE or PUR, ensuring flexibility and toughness in extreme cold.

Quality certifications: IEC 60245, UL 2464, CSA C22.2, CE

Pros and Cons: Maintain flexibility and insulation in freezing conditions, but not intended for high-heat or chemical environments.

Oil & Chemical-Resistant Cables

These cables are made to withstand oils, fuels, coolants, and chemical solvents, making them indispensable in automotive manufacturing, refineries, and machining workshops. The sheath materials—typically PUR, CPE, or neoprene—resist swelling, cracking, and corrosion caused by long-term chemical exposure.

Quality certifications: IEC 60811-404, UL 758, VDE 0282, RoHS

Pros and Cons: Strong resistance to oil and chemicals; slightly higher material cost, and may have a limited temperature range.

Marine & Offshore Cables

Used in ships, offshore drilling rigs, and port facilities, these cables must withstand saltwater, oil, vibration, and high humidity. They are often low-smoke, halogen-free, and certified by authorities like DNV, ABS, or Lloyd’s Register. The outer sheath resists UV, corrosion, and fire, ensuring safety and reliability in maritime operations.

Quality certifications: IEC 60092, DNV, ABS, Lloyd’s, CE

Pros and Cons: High durability and corrosion resistance; more expensive due to marine-grade materials and certification requirements.

Mining Cables

Mining cables are built for the toughest conditions—high mechanical stress, humidity, and abrasive surfaces. They have reinforced insulation, extra-thick sheaths, and tensile-strength members for safety and longevity. Common types include Type G-GC and Type SHD. These cables are the backbone of mining, tunneling, and heavy machinery operations.

Quality certifications: MSHA, ICEA S-75-381, UL 1650, CSA C22.2

Pros and Cons: Excellent toughness and shock resistance, but their thick structure limits flexibility and ease of handling.

Nuclear and Military-Grade Cables

These cables serve critical applications in nuclear power, aerospace, and defense systems. They must perform flawlessly under radiation, pressure, and vibration. Materials are selected for radiation resistance, low smoke emission, and long-term stability. Each batch undergoes strict MIL-Spec and IEC testing before deployment.

Quality certifications: MIL-C-17, IEC 60544, IEEE 383, CE, TÜV

Pros and Cons: Unmatched reliability and safety under extreme stress; production cost is high due to specialized materials and testing.

Key Information of Specialized Industrial Cables

| Cable Type | Applications | Construction | Technical Specs |

| Armored Cables | Underground or outdoor installations; high mechanical stress environments. | Copper or aluminum conductors; PVC/XLPE insulation; steel wire or steel tape armor; durable sheath. | 0.6/1–10 kV; –40 °C ~ +90 °C; strong mechanical protection. |

| Fire-Resistant & Flame-Retardant Cables | Emergency circuits, tunnels, airports, industrial buildings; maintain power during fire. | Copper conductors; LSZH or mica insulation; flame-barrier layers. | Survives up to 950 °C; 300/500 V–1 kV; flame-retardant. |

| High-Temperature Cables | Furnaces, glass & steel plants, engines; extreme heat areas. | Nickel-plated copper; silicone or PTFE insulation; heat-resistant sheath. | Up to +250 °C; 300/500 V–1 kV. |

| Low-Temperature Cables | Cold storage, outdoor sites, wind power; –40 °C and below. | Fine copper strands; TPE/PUR sheath; flexible in low temps. | Down to –60 °C; 300/500 V. |

| Oil & Chemical-Resistant Cables | Factories, workshops, chemical plants; oil or chemical exposure. | Copper conductors; PVC/PUR sheath; abrasion- and chemical-resistant. | –40 °C ~ +80 °C; 300/500 V; resistant to oil and chemicals. |

| Marine & Offshore Cables | Ships, ports, offshore platforms; wet and saline conditions. | Tinned copper; XLPE insulation; armored or halogen-free sheath. | –40 °C ~ +90 °C; 0.6/1 kV; salt- and moisture-resistant. |

| Mining Cables | Underground mines, tunnels, heavy machinery; high mechanical stress. | Copper conductors; reinforced insulation; armored sheath; high tensile strength. | 1.1–11 kV; impact-resistant; strong mechanical protection. |

| Nuclear & Military-Grade Cables | Nuclear plants, aerospace, defense systems; extreme radiation, pressure, and vibration. | Radiation-resistant copper or alloy; low-smoke halogen-free insulation; armored for stability. | Tested to MIL-Spec and IEC; –40 °C ~ +125 °C; high reliability under extreme conditions. |

Final Thoughts

Industrial cables come in many types and designs, yet they all serve the same purpose: to deliver power and data safely and reliably in challenging environments. Choosing the right cable can improve efficiency, reduce downtime, and help your equipment last longer.

At LX Wire and Cable, we provide one-stop solutions for high-quality industrial cables that meet international standards and diverse application needs. Whether you’re sourcing cables for automation, energy, or communication systems, our expertise and rigorous quality control ensure products you can rely on. With LX Wire and Cable, you get not just cables, but long-term reliability and a trusted partnership.