Overhead power cables form the backbone of modern electricity transmission, carrying energy across vast distances on towers and poles. Understanding what are overhead power cables made of is essential for engineers, utilities, and project planners, as material choice affects efficiency, mechanical reliability, and cost. This article explains their fundamental structure, compares common materials such as aluminum, copper, and ACSR, explores modern innovations, and highlights practical considerations for durability, maintenance, and application-specific selection.

What Are Overhead Power Cables Made Of? Core Materials Overview

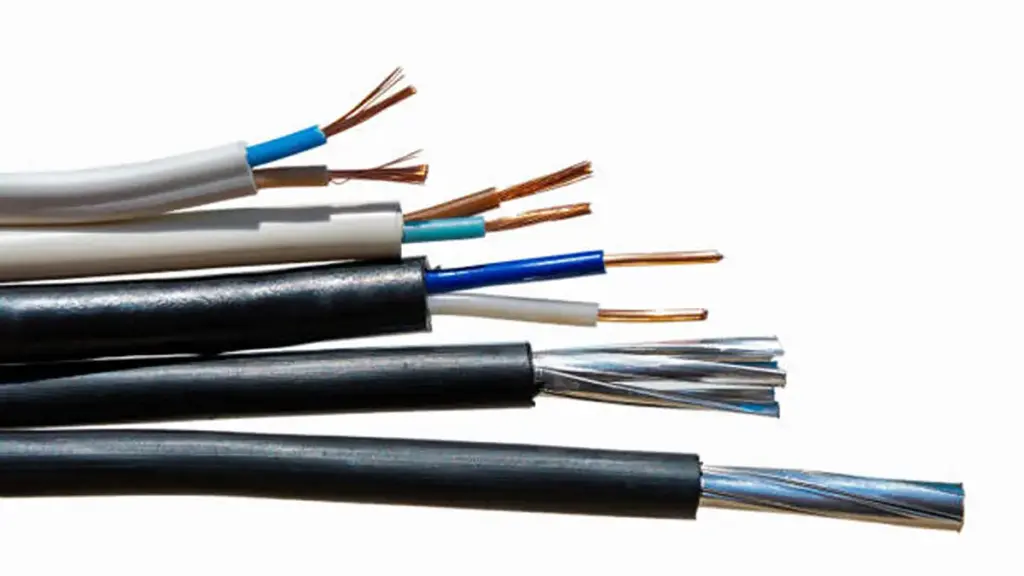

Overhead power cables are the primary medium for transmitting electricity across long distances, suspended on poles or towers rather than buried underground. At the most basic level, these cables consist of conductors that carry current and optional supporting or protective elements that ensure reliability under mechanical and environmental stress. Typical compositions include:

- Aluminum Conductors (AAC/AAAC): Stranded aluminum or aluminum alloy wires form the main pathway for electricity. Their light weight reduces stress on towers and allows larger diameters to compensate for lower conductivity.

- Aluminum Conductor Steel-Reinforced (ACSR): Aluminum strands are wrapped around a steel core, which provides extra tensile strength. This design is widely used for high-voltage and long-span lines.

- Copper Conductors: Less common today but known for high conductivity and durability. Copper is typically used in shorter spans or specialized settings where compact cross-sections are needed.

- Insulation and Coatings: Many overhead lines are bare, but some modern designs include polymer coatings or cross-linked polyethylene (XLPE) layers for added protection in urban or harsh environments.

Together, these components balance electrical performance, mechanical strength, and cost for reliable energy delivery.

Aluminum vs Copper vs ACSR: Key Properties and Performance Comparison

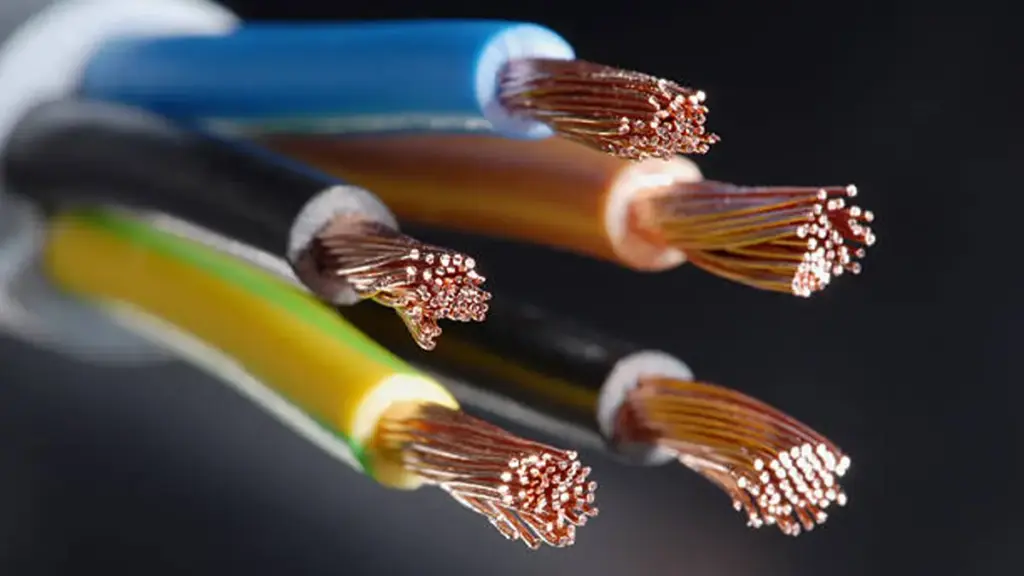

Copper

Copper is historically the most widely used conductor material due to its excellent electrical conductivity—it serves as the baseline for measuring other materials. Hard-drawn stranded copper has high tensile strength, making it suitable for shorter spans or applications requiring compact cross-sections. Copper’s high current density allows for smaller diameter wires with the same power capacity compared to aluminum. It also offers superior durability and a high scrap value, which benefits recycling efforts. However, copper’s significant weight increases structural demands on towers, and its high cost combined with susceptibility to theft limits its use in large-scale overhead transmission lines today.

Aluminum (AAC/AAAC)

Aluminum conductors, including All-Aluminum Conductor (AAC) and All-Aluminum Alloy Conductor (AAAC), are favored for modern grids due to their lightweight nature (roughly one-third the weight of copper) and relatively low cost. Although aluminum’s conductivity is about 61% that of copper, its lower density allows for larger diameters that achieve similar current-carrying capacity without excessive weight. Aluminum forms a natural oxide layer, providing good corrosion resistance in most environments. Its lower tensile strength compared to copper means it is often used in shorter spans or combined with reinforcement for longer distances.

ACSR (Aluminum Conductor Steel-Reinforced)

ACSR combines aluminum strands with a central galvanized steel core, enhancing tensile strength and reducing sag under mechanical and thermal loads. This makes it ideal for long-span transmission lines and high-tension applications. The aluminum outer strands provide conductivity, while the steel core supports mechanical stress from wind and ice. ACSR offers a balanced compromise: more economical than pure copper, stronger than AAC or AAAC, and widely standardized (e.g., ASTM B232). However, its steel core requires protective coatings or greases to prevent corrosion over decades of service.

Otros materiales

- Aluminum Conductor Steel-Supported (ACSS): Similar to ACSR but designed to operate at higher temperatures (up to 200°C) with reduced sag, useful for grid uprating.

- Composite Core Conductors (e.g., ACCC, ACCR): Use carbon or glass fiber cores to reduce weight and thermal expansion, improving energy efficiency and long-span performance.

- Copper-Clad Steel: Combines copper’s conductivity with steel’s tensile strength, occasionally used where both strength and conductivity are critical, though less common in mainstream transmission.

These alternatives address evolving needs such as higher operating temperatures, improved efficiency, and enhanced durability under extreme environmental conditions.

Structural Components Beyond Conductors

While the conductor material answers most of what are overhead power cables made of, several critical components ensure operational reliability:

Steel Core Reinforcement

A galvanized steel core is used in ACSR and similar conductors to provide tensile strength, minimize sag over long spans, and support high mechanical loads from wind or ice.

Insulators

Ceramic, glass, or polymer insulators physically separate energized conductors from supporting towers, maintaining required clearances and preventing leakage currents even in contaminated or wet conditions.

Protective Coatings

Zinc galvanization or grease layers are applied to steel components to prevent corrosion and extend service life, especially in coastal or industrial environments with aggressive atmospheres.

Messenger and Ground Wires

Messenger wires provide structural support for bundled conductors, while optical ground wires (OPGW) combine lightning protection with integrated fiber-optic communication for grid monitoring.

Hardware and Fittings

Clamps, vibration dampers, and spacers secure conductors to towers, reduce mechanical stress, and control oscillations caused by wind, ensuring stable and safe operation over decades of service.

These non-conductive elements, though secondary to the conductor, play a vital role in ensuring reliability and meeting safety regulations under standards like IEC 60888 for zinc-coated steel wires used in overhead conductors.

Practical Considerations: Material Selection, Durability, and Maintenance

Material Selection by Voltage Level

Material choice for overhead power cables is closely linked to the operating voltage, mechanical loading, and environmental conditions of the installation site. Different voltage levels require specific conductor types to ensure reliable performance and manageable lifecycle costs. The table below summarizes common voltage classes, preferred materials, and their key attributes:

| Voltage Level | Typical Materials Used | Características | Solicitud |

| Low Voltage (<1 kV) | Copper or small-diameter aluminum | High conductivity, compact size; often insulated | Urban or residential distribution networks |

| Medium Voltage (1–69 kV) | AAC or AAAC | Lightweight, economical, moderate tensile strength | Distribution feeders with moderate spans |

| High Voltage (69–230 kV) | ACSR | Good conductivity, high tensile strength, balanced cost | Long-span transmission lines and heavy load conditions |

| Extra High Voltage (>230 kV) | ACSR, ACSS, or HTLS conductors | High strength, low sag at high temperatures, supports higher capacity | Extra-long-distance or ultra-high-voltage transmission corridors |

Durability and Environmental Challenges

Beyond voltage considerations, durability and maintenance factors strongly influence material selection. Aluminum forms a protective oxide layer, offering natural corrosion resistance, while steel-reinforced conductors require galvanization or grease coatings to prevent rust in humid or coastal environments. Wind-induced vibrations, temperature cycling, and ice loading can accelerate mechanical fatigue; thus, dampers, spacers, and periodic inspections are integral to long-term reliability.

Lifecycle Cost and Safety Assessment

From a sustainability perspective, both aluminum and copper are highly recyclable, lowering environmental impact and providing scrap value at end-of-life. Utilities also assess lifecycle costs, balancing initial material expense against expected maintenance frequency and performance stability. Incorporating these operational considerations ensures overhead power cables meet safety standards and deliver dependable service over decades of operation.

Modern Innovations: Composite and High-Temperature Low-Sag Conductors

Emerging technologies address the limitations of traditional materials. Composite core conductors, such as ACCC (Aluminum Conductor Composite Core), replace steel with carbon or glass fiber cores, reducing weight and thermal expansion. HTLS conductors maintain higher operating temperatures (up to 200°C) without excessive sag, enabling utilities to uprate existing lines without new towers.

These innovations respond to the growing demand for grid upgrades to support renewable energy integration and higher load densities. They also offer improved energy efficiency by reducing line losses, a critical factor in long-distance transmission.

Choosing the Right Material for Overhead Power Cables

Selecting the right material involves balancing conductivity, mechanical strength, environmental resistance, and cost over the cable’s entire service life. Copper may be preferred for compact installations, while aluminum-based conductors such as AAC, AAAC, or ACSR remain the standard for most transmission and distribution networks due to their light weight and cost efficiency.

For projects requiring certified quality and customization, Cable LX offers overhead power cables in ACSR, AAAC, and other configurations. Their solutions come with OEM & ODM options, CE and RoHS certifications, a one-year quality guarantee, and over 25 years of manufacturing experience.

Contact LX CABLE to discuss tailored designs that meet performance standards and ensure reliable long-term operation in diverse grid environments.