Cable screening is something you hear often in electrical engineering, yet many buyers are not fully sure what it is. If you deal with power systems, automation lines, or data equipment, understanding this concept helps you avoid costly interference issues.

Cable screening, or shielding, is a protective layer added to an electrical cable. It protects the internal conductors from external electromagnetic interference (EMI) and prevents the cable from emitting its own interference.

This article will serve as your comprehensive guide to cable screening, delving into its meaning, different types, essential applications, and how to make the best selection for your specific needs.

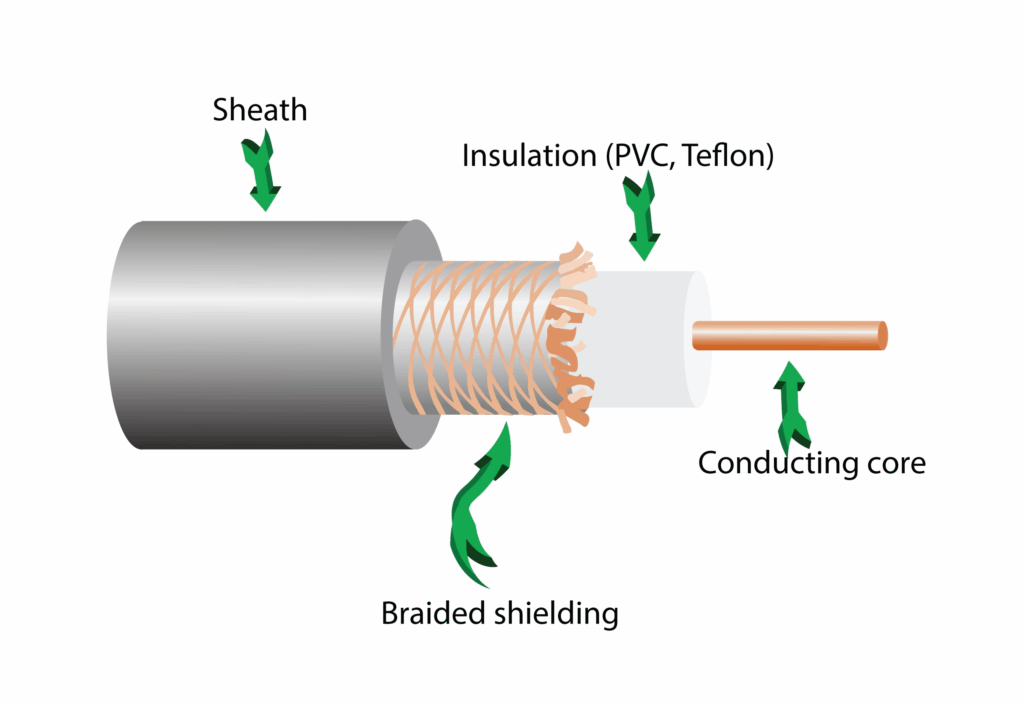

Understanding Cable Screening: A Look Inside the Coaxial Cable

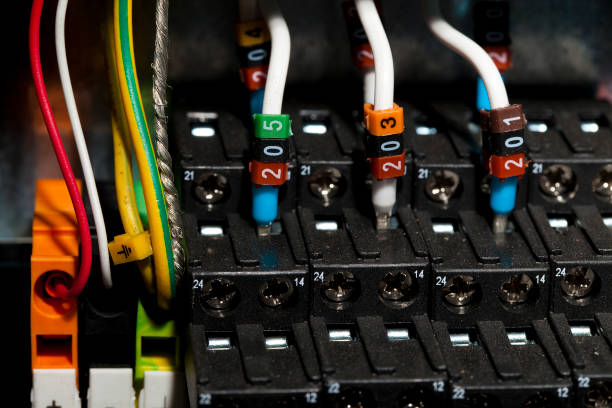

The reliability of modern communication hinges on a critical concept: cable screening (or shielding). Simply put, it is the practice of wrapping a protective, conductive layer around the signal-carrying components of an electrical cable. The most common and effective example of this is the coaxial cable. The following diagram perfectly illustrates the layers of engineering involved in creating a shielded cable:

As the illustration shows, a robust cable is built from the outside in, with key components designed specifically for defense: the braided shielding and the Sheath. The braided shielding is the functional screen that makes cable shielding possible.

The core purpose of screening can be summarized in three points.

- it blocks unwanted electromagnetic interference (EMI), so signals stay accurate.

- it improves safety by reducing the chance of mis-triggered sensors or control failures.

- it reinforces signal integrity, which is especially important in industrial automation, network communication, and high-frequency transmission.

Different Types of Cable Screening

Below are the three major types you’ll see across industrial and communication cable families.

Braid Shields

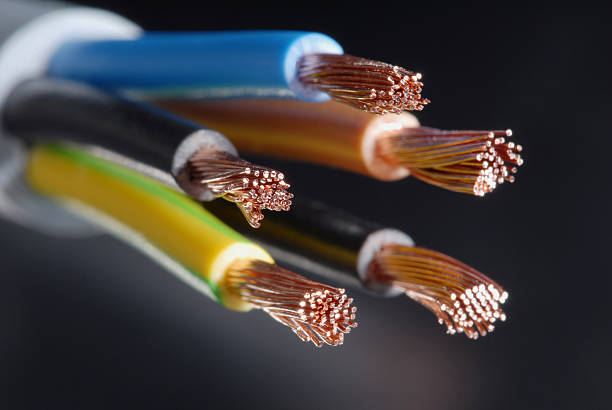

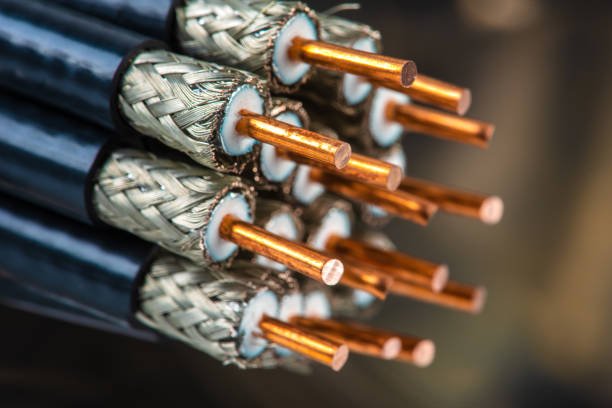

A braid shield consists of small strands of copper or tinned copper woven together to form a mesh layer around the conductors.

- Pros: Excellent mechanical strength; very good low-frequency shielding; highly flexible and robust against repeated bending.

- Cons: More expensive than foil; coverage is less than 100%, leaving small “holes.”

- Typical Coverage: Coverage is usually specified by percentage, commonly ranging from 65% to 95%. A higher percentage offers better shielding but reduces flexibility.

Braid shields are highly effective at blocking lower-frequency interference, making them a common choice for industrial control cables and specific types of communication lines.

Foil Shields

A foil shield is a thin layer of aluminum or copper laminated onto a polyester carrier tape. This construction is lighter and thinner than a braid.

- Pros: 100% coverage, offering superb high-frequency shielding; small diameter and lightweight; lower cost.

- Cons: Less mechanical strength; difficult to terminate; poor effectiveness against low-frequency interference.

- Best Uses: Ideal for high-speed data cables (like those used in computer networks) where high-frequency noise is the main concern.

The 100% coverage is a key factor. It essentially creates a continuous barrier against radiated emissions at higher frequencies, often performing better than a braid in that specific range.

Combined Shielding Systems

Many high-performance cables, especially in networking and high-speed data transmission, utilize a combination of shields. This dual-layer approach leverages the strengths of both braid and foil.

For example, an S/FTP (Screened/Foiled Twisted Pair) cable uses an overall braid shield (Screened) around the entire bundle of conductors and an individual foil shield (Foiled) around each twisted pair. This design offers a multi-layered defense:

- The individual foil shields prevent crosstalk between pairs.

- The outer braid shield protects the entire cable from external EMI.

This construction is the gold standard for high-noise environments and the most demanding data rates.

Quick Comparison Table

| Shield Type | Coverage | Flessibilità | Low-Frequency Effectiveness | High-Frequency Effectiveness | Best Used For |

| Braid | Typically 65-95% | Alto | Very Good | Good | Industrial control, VFD, audio |

| Foil | 100% | Basso | Poor | Excellent | Data cables, Ethernet |

| Combined | 100% (Foil) + % (Braid) | Moderare | Excellent | Excellent | Harsh or mixed EMI environments |

Where and Why Screened Cables Are Required

Screened cables are a necessary component in environments where signal reliability is non-negotiable.

Variable Frequency Drives (VFDs)

VFDs are notorious for generating significant high-frequency noise (EMI) as a byproduct of switching high currents. Running an unscreened motor cable near a VFD could lead to catastrophic failure in sensitive control circuits. A shielded cable, typically one with a tight braid or combined shield, is essential to contain this noise.

Industrial Automation and Networks

In factory settings, control cables often run alongside high-voltage power cables and near equipment that generates transient noise (e.g., welding machines, solenoids). Networks like PROFINET or DeviceNet often mandate the use of shielded cables to maintain the integrity of their data packets.

High-Speed Data Transmission

For Category 6A, Category 7, and Category 8 Ethernet cables, screening manages both external noise and internal signal radiation (Alien Crosstalk). Without the screen, achieving 10 Gbps or 40 Gbps transmission speeds reliably is extremely difficult over typical distances.

Medical Equipment

Devices in hospitals must be free from electrical noise to ensure patient safety and accurate readings. Screened cables prevent external interference from affecting sensitive diagnostic tools like MRIs or ECG machines.

In all these scenarios, the underlying requirement is the same: the environment is electromagnetically aggressive, demanding a robust defense mechanism to ensure system function and longevity.

Screened vs. Unscreened Cables: A Guide to Selection and Noise Immunity

The choice between screened and unscreened cables is fundamentally a risk assessment based on the operating environment.

The Risks of Using Unscreened Cables

An unscreened cable (often UTP, or Unshielded Twisted Pair) relies solely on the inherent noise cancellation properties of its twisted conductors. In a quiet, controlled environment, this is often sufficient. However, placing an unscreened cable in a noisy environment poses several significant risks:

- System Downtime and Errors: Data corruption leads to operational errors, forcing costly system restarts and downtime.

- Induced Voltage: In some high-power applications, noise can induce voltage spikes, potentially damaging connected electronics.

- Emission of Noise: The cable itself can become an antenna, broadcasting the signal noise and interfering with other nearby equipment—a critical issue for compliance with EMC (Electromagnetic Compatibility) standards.

Guiding Your Choice

| Fattore | Unscreened Cable (UTP) | Screened Cable (STP, FTP, etc.) |

| Environment | Electromagnetically Quiet (e.g., residential, separate low-voltage conduits) | Electromagnetically Noisy (e.g., industrial, near motors, fluorescent lights) |

| Cost | Inferiore | Più alto |

| Installation | Easier, more flexible | Stiffer, requires careful grounding/termination |

| Data Rate | Up to 1 Gbps (Cat 5e/6) | 10 Gbps and above (Cat 6A/7/8) |

| Assessment | Low risk tolerance for noise | High performance, mission-critical applications |

Pro Tip: Choosing the right cable is about noise immunity. If there is any doubt about the level of noise in the operating environment, the professional choice is always to use a shielded cable. The upfront cost of a screened cable is consistently lower than the cost of troubleshooting and fixing noise-related system failures later on.

How to Choose the Right Screened Cable for Your Needs

Here are the key factors you need to consider when choosing the optimal screened cables.

Environment and Noise Type

- High-Frequency Noise (e.g., digital electronics, Wi-Fi): You’ll get the best results with a foil shield, thanks to its nearly 100% coverage.

- Low-Frequency Noise (e.g., power line harmonics, motor fields): You should choose a braid shield, which performs better at lower frequencies.

- Extremely Noisy Settings: If you’re working near VFDs or heavy machinery, a combined shield (S/FTP) is often the only reliable choice.

Frequency Range (Signal Speed)

If your cable will handle high data rates, you need stronger screening to prevent signal radiation and maintain transmission performance. For example, a cable like Cat 6A must support a maximum frequency above 500 MHz. Checking this ensures you’re not under-specifying for your application.

Flexibility and Installation

If your setup involves constant movement, such as robotics or drag chains, you should select a high-percentage braid shield. Foil shields tend to tear or delaminate under repeated stress. In these cases, you must specify a high-flex-rated cable material in addition to the shield type.

Cost and Termination

Screened cables cost more than unscreened ones. Moreover, the termination process (connectorizing) is more complex. You must properly ground the shield; otherwise, the cable may perform worse than a correctly terminated unscreened cable. This means you’ll need specialized connectors and careful attention during installation.

Industry Tip: Always check the cable’s transfer impedance specification. This parameter, measured in mΩ/m (milli-ohms per meter), is the most reliable measure of a screen’s effectiveness. Lower transfer impedance indicates better shielding performance across a specified frequency range.

Final Thoughts

Cable screening is not complicated once you understand what each shield type does and how interference affects your system. A screened cable prevents noise problems, protects your equipment, and ensures your signals stay stable.

At LX Wire and Cable, we focus on delivering reliable and well-engineered cable solutions backed by more than 20 years of manufacturing experience. We offer a wide product range, including cavi di alimentazione, overhead conductors, E cavi solari, etc. OEM customization is also available, and we can supply related electrical accessories to simplify procurement for global customers. If you need technical guidance or project-specific recommendations, our engineering team is ready to support your requirements.

Ready to upgrade your system with stable, interference-resistant cable solutions?

Contact us today to get expert advice and a quote tailored to your project.